Our final check before you come on board

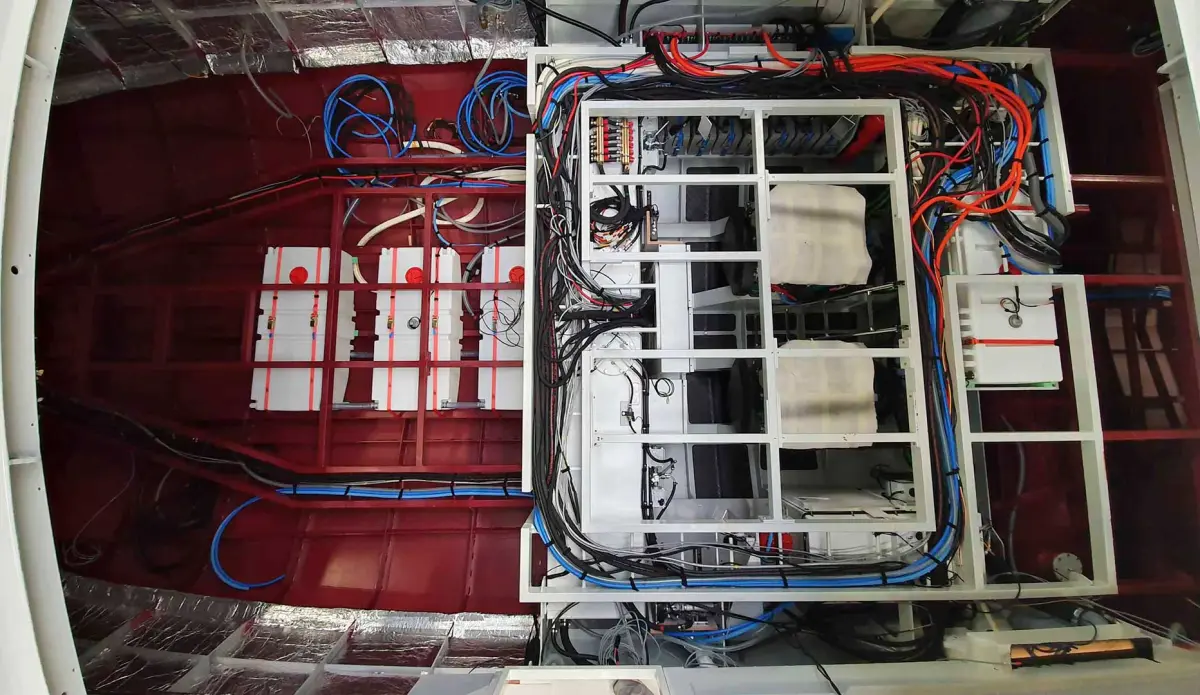

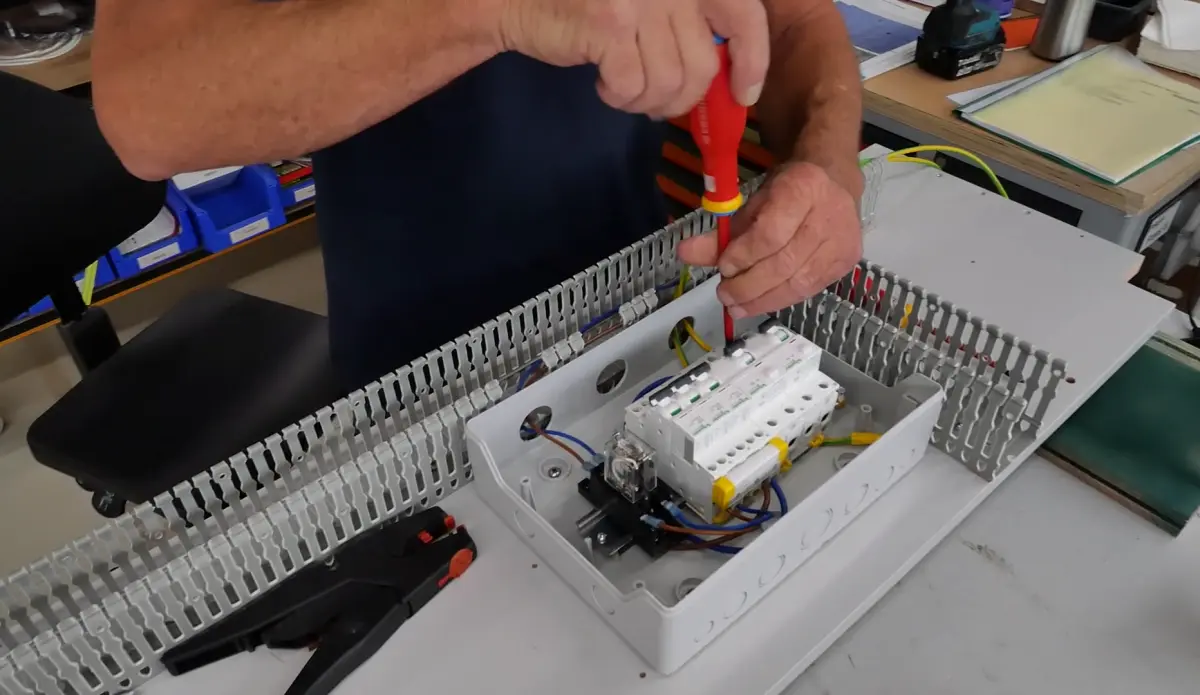

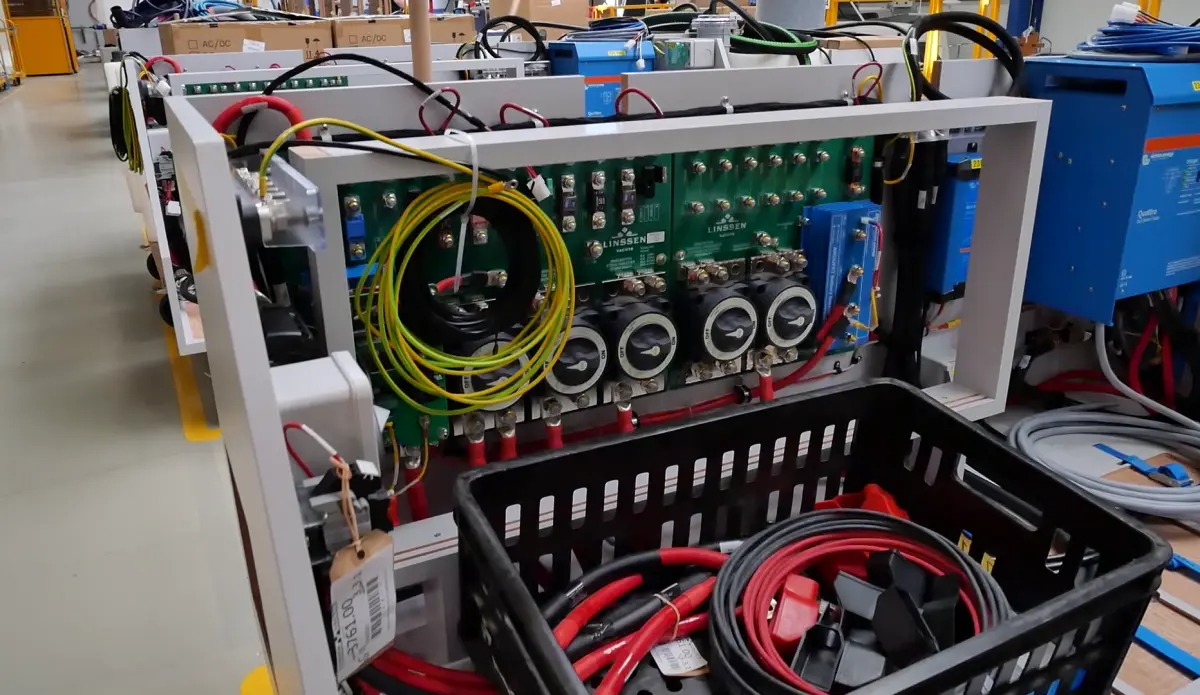

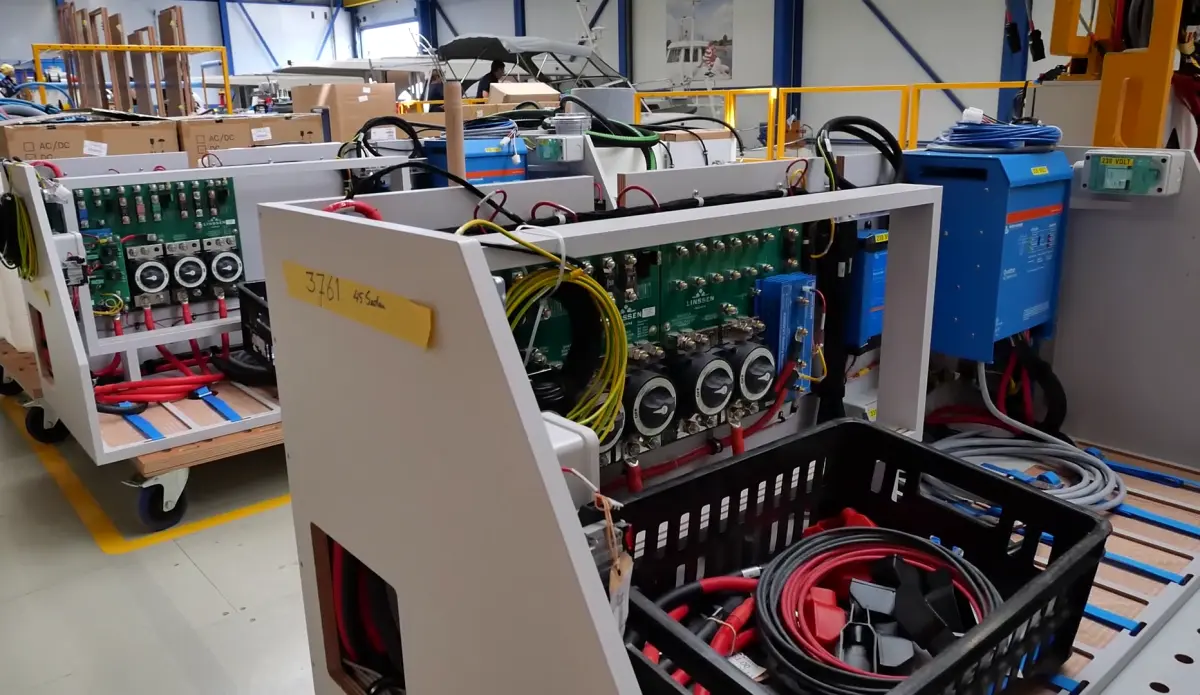

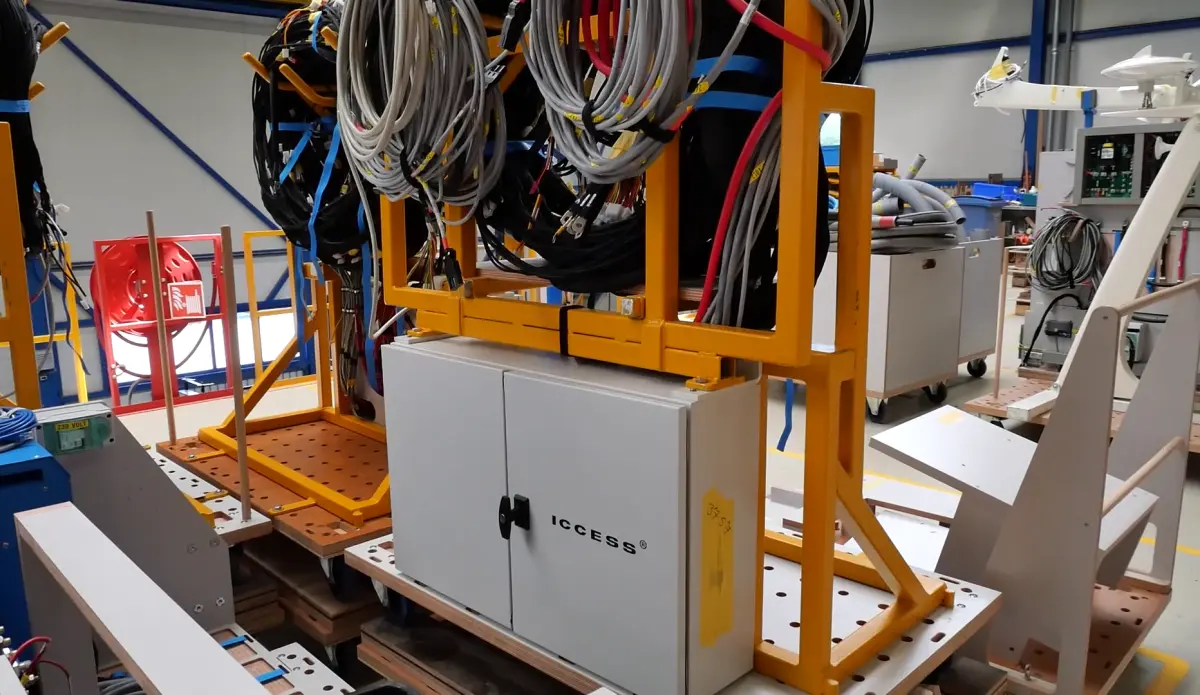

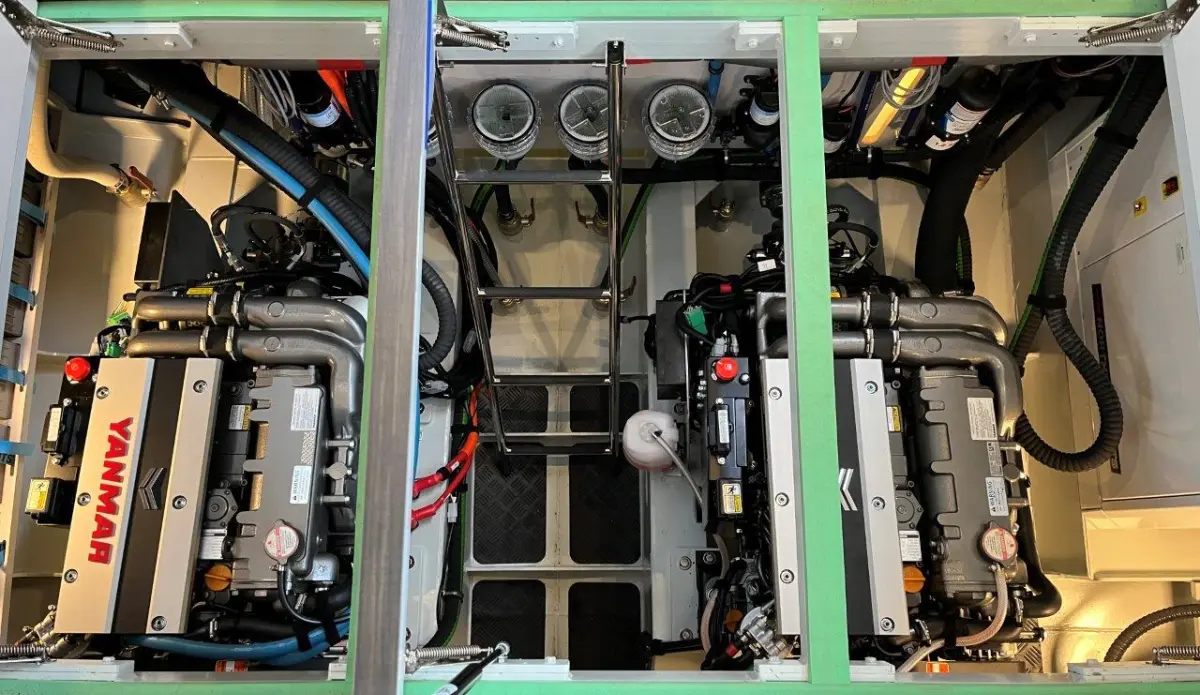

Before you board your new Linssen yacht, we conduct a thorough final check. We carry out various quality checks and tests, inspecting your yacht inside and out on a large number of points. We run through all systems on board according to set checklists. We carry out some checks outdoors, such as testing watertightness.

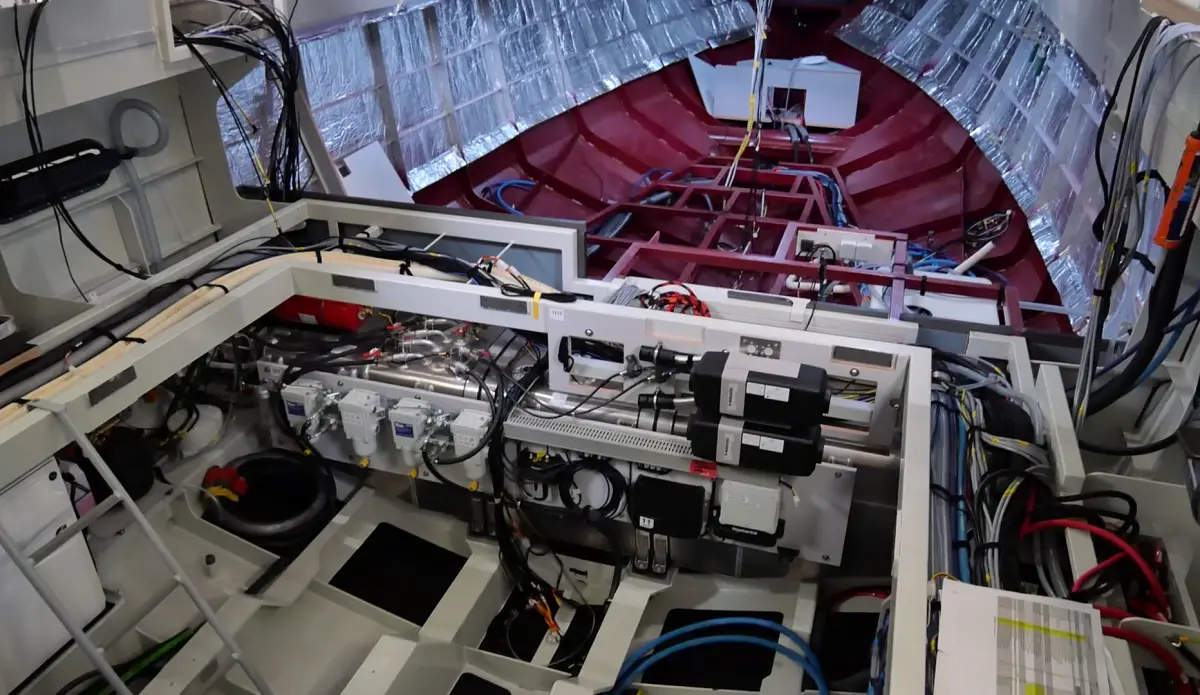

Commissioning your yacht

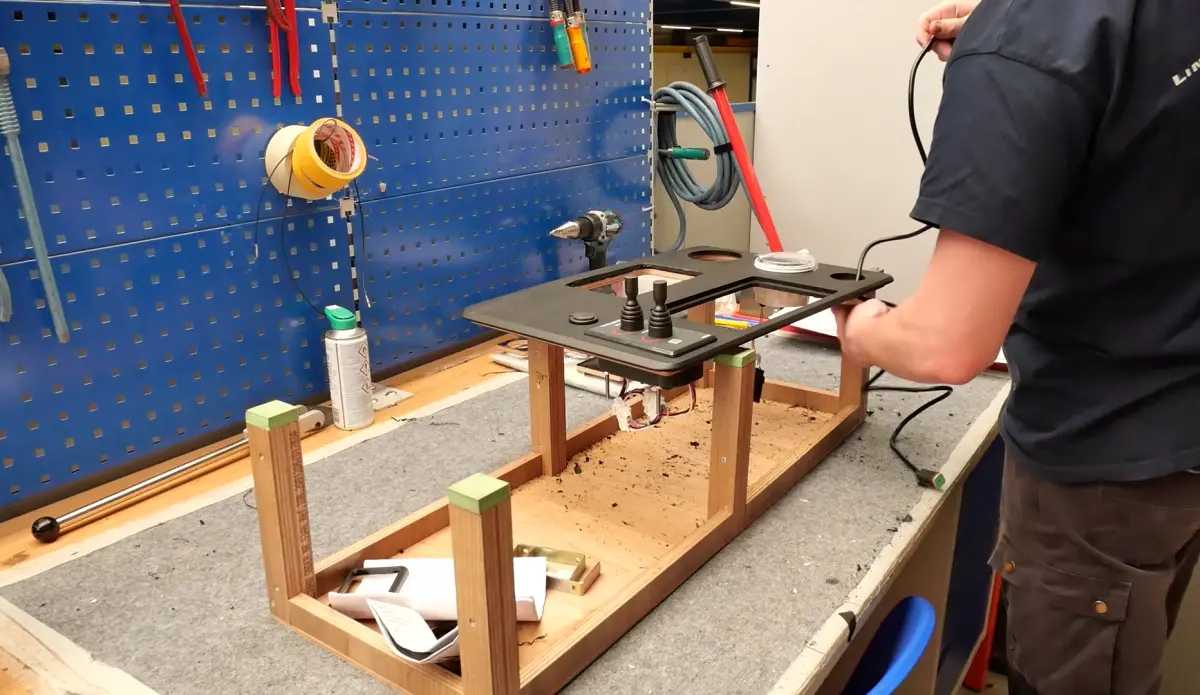

When your yacht has passed its final inspection, we launch it in our own marina and start the official commissioning. We fine-tune systems such as navigation, steering and the power system. We also pay a lot of attention to adjusting and fine-tuning the power train. It is therefore important to assess the sailing characteristics during a test sailing.

Test sailing(s)

In this final phase before handover, we carry out several test sailings. Not only to gain a general impression of your new yacht, but in particular to properly fine-tune the power train. These test sailings are carried out by specialists from different departments. Once we are satisfied with the test results, your yacht will be ready for the handover.

Handover and first sailing: we take our time

We allocate a lot of time for the handover. Allow for a full day. And we do the same when you buy a used Linssen yacht. We really need that time.

We start by checking together that we have delivered everything we agreed on. We will also provide you with comprehensive technical instructions. We tell you where to find everything and how everything works. And how to use the handbook and instructional videos. Of course, you will be given every opportunity to ask any questions you have. And to test what you want to test.

Once everything is clear, we leave our marina for your very first sailing. You can then get used to your new Linssen, but above all enjoy your yacht. A day later, we sail again together for an extended trip through locks. We do this as standard to further familiarise you with the features of your new yacht, for example during mooring and manoeuvring.

After the festive handover, you can move in and arrange everything in your new yacht. For this purpose, we offer you a free mooring in our own marina.

Read also: Linssen Start Boating.