Prevention is better than insulation

- Details

Smart concept for noise reduction on board

“How is it possible that you have such quiet motor yachts?” We are regularly asked this question. As builders of luxury motor yachts, we have always attached great importance to the development of quiet boats. Unfortunately, sailing without any noise at all is not (yet) feasible. But at Linssen Yachts we do everything we can to achieve the lowest possible noise level on board. We work according to a 10-step plan, the foundations for which were laid in our company at the end of the 1970s. What is at the heart of our approach? Noise prevention is better than insulation.

You will know by now that at Linssen Yachts it’s in our nature to aim for the highest attainable standards. This therefore includes noise reduction. Over the years, our engineers have been continuously developing new solutions to further reduce noise and vibrations. All the components of our propulsion concept have been examined in detail and improved in several respects.

Our step-by-step plan consists of 10 engineering solutions that are for the most part “invisible” on board a Linssen. Without wanting to turn this into a technical treatise, we’d like to explain these in-house noise reduction measures, known as our Noise Prevention System (NPS).

The comfort of silence

On board our motor yacht series you will find the perfect conditions in which to enjoy life slowly and intensely. Our constant attention to noise reduction should therefore be seen in that light. The quieter it is on board, the more relaxed and comfortable you feel. And the better you can enjoy the sounds that are “desirable”. For example, the gentle lapping of the water against the hull. The whispering of the wind. Or a pleasant conversation with your fellow travellers on the aft deck. But maybe there’s no sound at all. Only a deafening silence, thanks to our Noise Prevention System (NPS). That, to us, is pure luxury as well. Slow down and start living.

(1) Solid engine bed

Effective noise control starts with the basics. We have therefore laid a solid bed (Dual Cross) under our engines in the engine room, to spread the forces evenly in all directions.

(2) Extra-soft vibration dampers

In all our yachts, the engines are placed on extra-soft vibration dampers on top of the bed. These “rubber feet” ensure that vibrations from the engines cannot be transferred to the bed.

(3) Silent diesel engines

There are many types of engines, each with its own characteristics. Our yachts are equipped with modern diesel engine(s). With excellent displacement performance, low noise levels and low fuel consumption.

(4) Limitation of reverse gear

If a propeller starts to turn too fast, it will slip. This causes air bubbles (cavitation) and these bubbles produce sound. To prevent this, we have limited the maximum speed using the reverse gear. This means that the propeller shaft can’t rotate at more than 1,000 revolutions per minute.

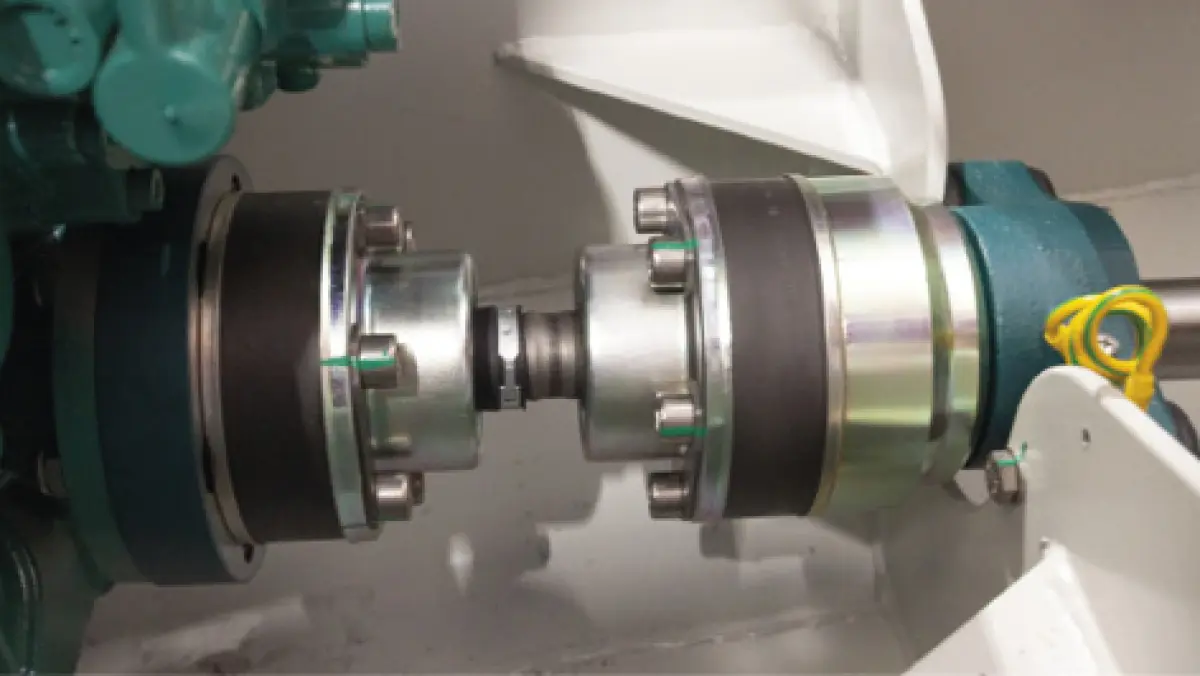

(5) Flexible coupling between engine and propeller shaft

We have placed what is known as a homokinetic coupling between the engine and the propeller shaft. This flexible coupling allows the engine and propeller shaft to move completely independently of each other. This prevents vibrations from being transmitted.

(6) Absorbent thrust bearing

The propeller on the thruster pushes the boat forward. The propeller shaft wants to move in the direction of the engine and theoretically could push the engine off its vibration dampers.

We have installed a special rubber-mounted thrust bearing to absorb the vibrations of the propeller shaft.

(7) Multilayer insulation of propeller shaft

The propeller shaft has several layers of different materials wrapped around it. This combination makes for an excellent insulation system, in which the vibrations of the propeller shaft can be easily absorbed. The insulation system is built up as follows (see illustration):

1. Steel on the outside

2. Rubber clamping seal

3. Polyester inner tube

4. Brass bearing

5. Rubber inner bearing

6. Water lubrication

7. Propeller shaft

This layered structure makes any direct contact between metals impossible. Everything sort of “floats” relative to everything else, as a result of which hardly any vibrations at all can be transmitted. And that’s exactly why we do it this way.

(8) Quiet propeller

Propellers are also available in all shapes and sizes. We have chosen a 4-bladed propeller that is designed for use at low speeds and low-noise propulsion. It’s essential to maintain the correct distance between the propeller and the hull. This must be at least 20% of the propeller’s diameter. Why? Because the noise transmission from the propeller to the hull is relatively low at that distance.

(9) Power Impact Construction (PIC)

We have filled a completely closed section in the hull, directly above the propeller, with fine dry sand. We call this the Power Impact Construction (PIC). The enormous force that the propeller transmits to propel our yachts causes vibrations. This kind of vibration can best be compared to a hammer blow against the bottom of the boat. With a 4-bladed propeller turning at a speed of 1,000 rpm, that makes 4,000 hammer blows per minute. Because of our “sandbox construction” these sound waves are deadened against the bottom of the boat.

(10) Engine room insulation

All internal combustion engines produce noise, including our near-silent Volvo Penta diesel engines. To give that last bit of noise little or no chance to escape, we have insulated our engine room extremely well.

(9) Power Impact Construction (PIC)

We have filled a completely closed section in the hull, directly above the propeller, with fine dry sand. We call this the Power Impact Construction (PIC). The enormous force that the propeller transmits to propel our yachts causes vibrations. This kind of vibration can best be compared to a hammer blow against the bottom of the boat. With a 4-bladed propeller turning at a speed of 1,000 rpm, that makes 4,000 hammer blows per minute. Because of our “sandbox construction” these sound waves are deadened against the bottom of the boat.

(10) Engine room insulation

All internal combustion engines produce noise, including our near-silent Volvo Penta diesel engines. To give that last bit of noise little or no chance to escape, we have insulated our engine room extremely well.