Hello, I am build number 3958 – your future, proud 40 SL AC Expedition Edition!

- Details

You may not know me yet, but I already know exactly who I am. I am not just any motor yacht: I am the 425th motor yacht coming to life on the Logicam II production line. A line reserved especially for the larger yachts among us: the 40- and 45-foot models. And to be honest, I’m quite proud of that.

If you visit me soon, you might already see some of my future parts waiting: doors, windows, upholstery and accessories. Just a few more weeks and I will be complete – ready for my first test run, when I will prove that I am not only good-looking but also perfectly seaworthy.

An Expedition Edition with a mission

I am no ordinary Linssen. As an Expedition Edition, I am built to explore the most beautiful cruising grounds – from winding rivers to distant shores. My mission? To offer you unforgettable journeys, in silence, luxury and safety.

So if you see me soon at the yard, don’t hesitate to wave. I am build number 3958, and I can’t wait to explore the world with you.

Allow me to share my story with you. Because although I am still in the middle of my transformation, I have already experienced a lot:

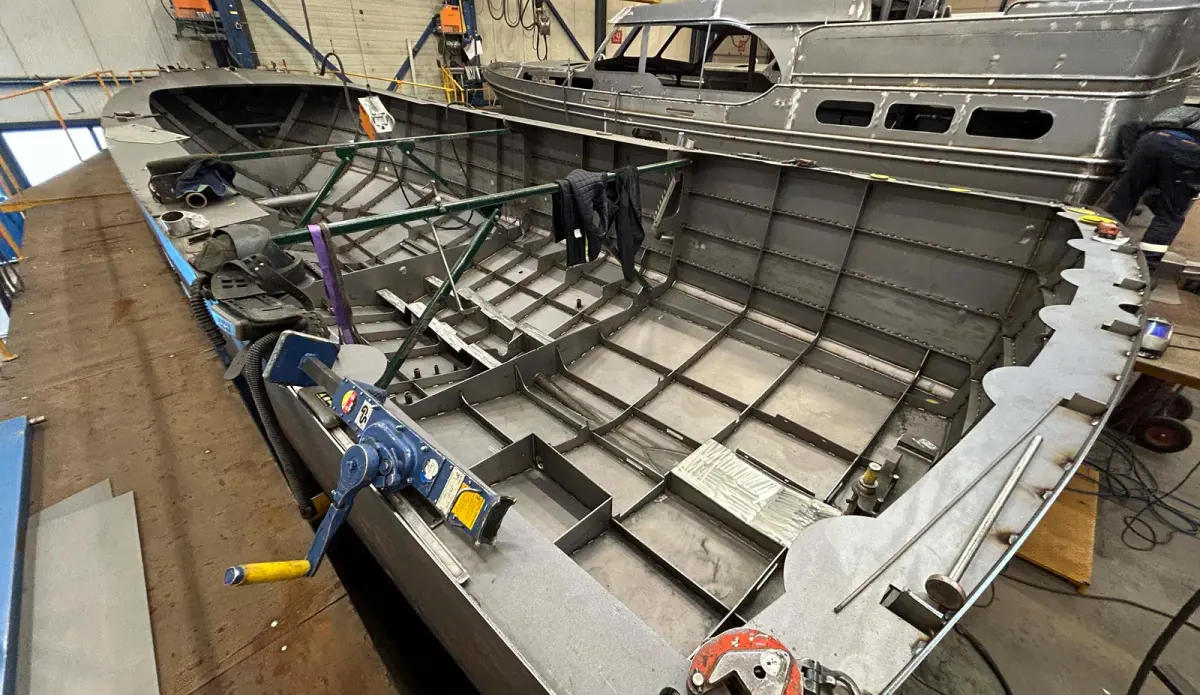

My steel birth

My story begins in early January when the steel for my torso is cut out in detail with a laser. Dozens, hundreds of smaller and larger pieces of steel that will soon define my face.

Everything started when my sturdy hull plates were meticulously welded together. What were once separate sheets of steel slowly became my backbone. You should have seen me then: still bare and grey, but full of potential.

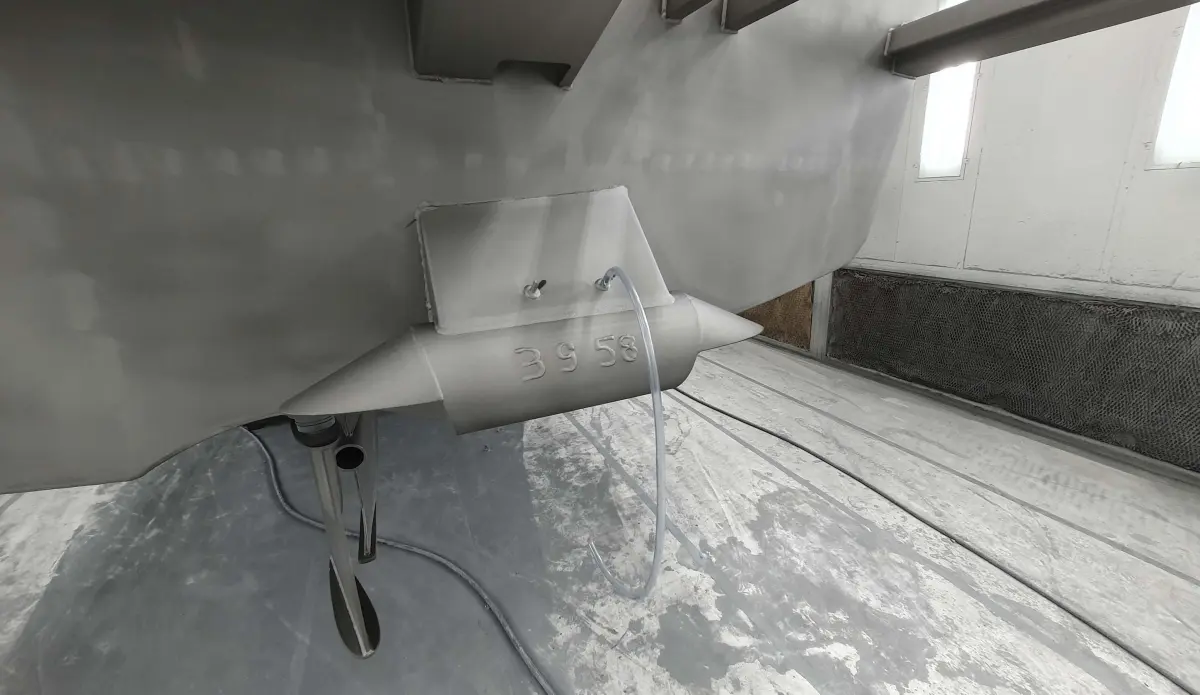

Blasting and coating

Next, I received an intensive spa treatment. I was thoroughly blasted, to be perfectly clean and roughened up, ready for protection. Then I was dressed in my first real outfit: multiple layers of high-quality coating to keep me looking great and well protected for decades to come.

Railing and teak deck

I have my coat on and am now being driven to the next hall. There I get a nice stainless steel railing mounted all around on my shoulders. Other people spend days laying all custom-made teak slats. I immediately feel a whole lot nobler with such a nice teak deck. On the inside comes a layer of insulation to prevent condensation on the waterline.

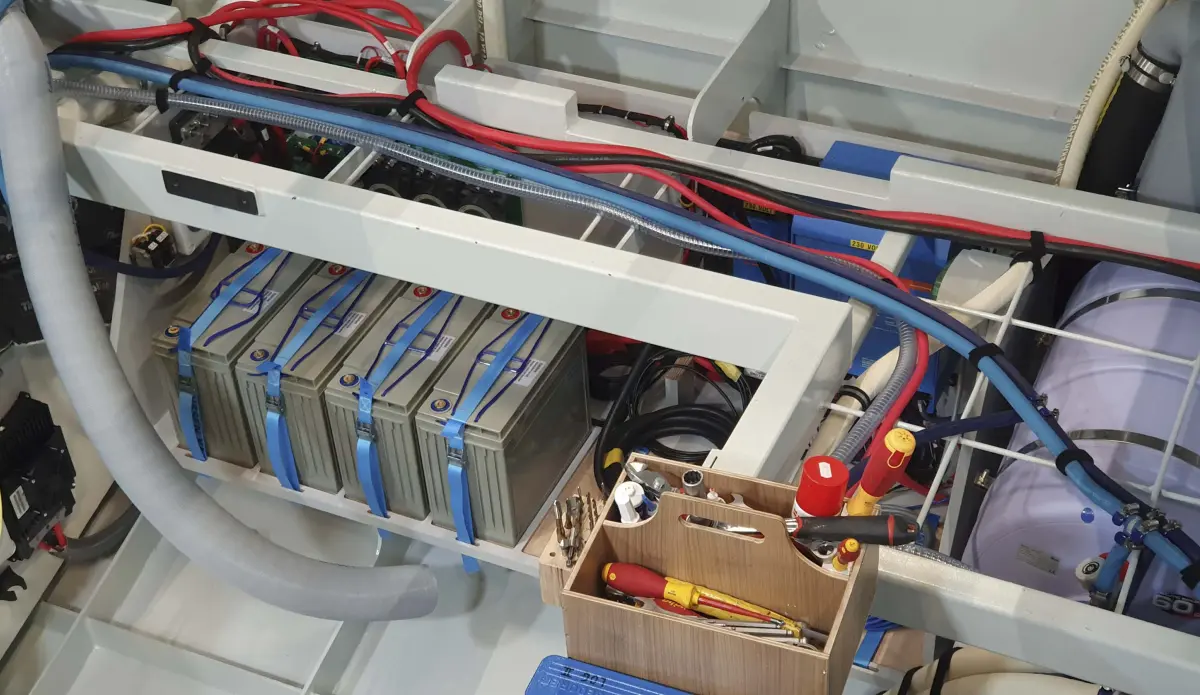

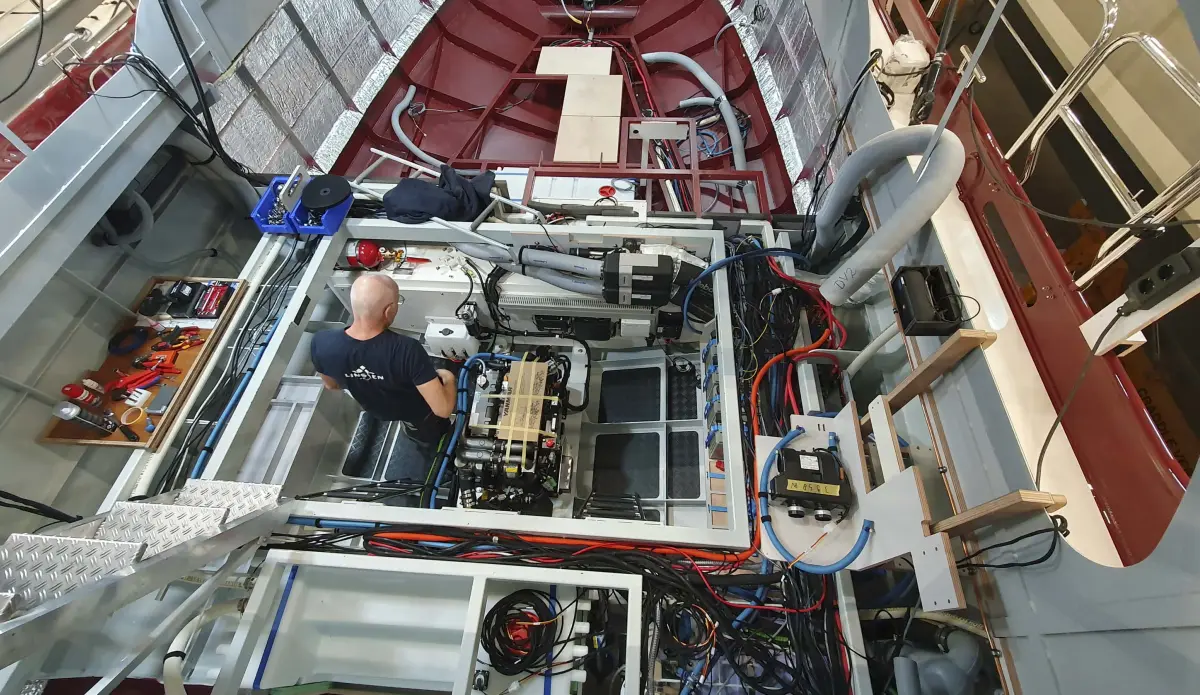

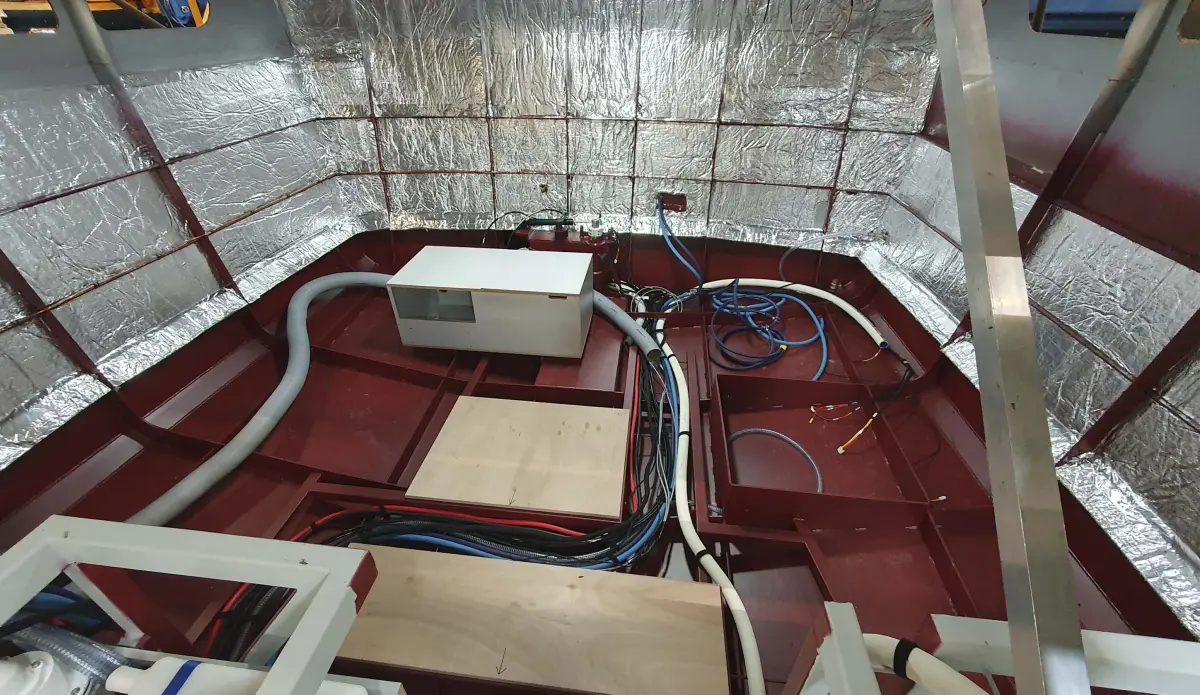

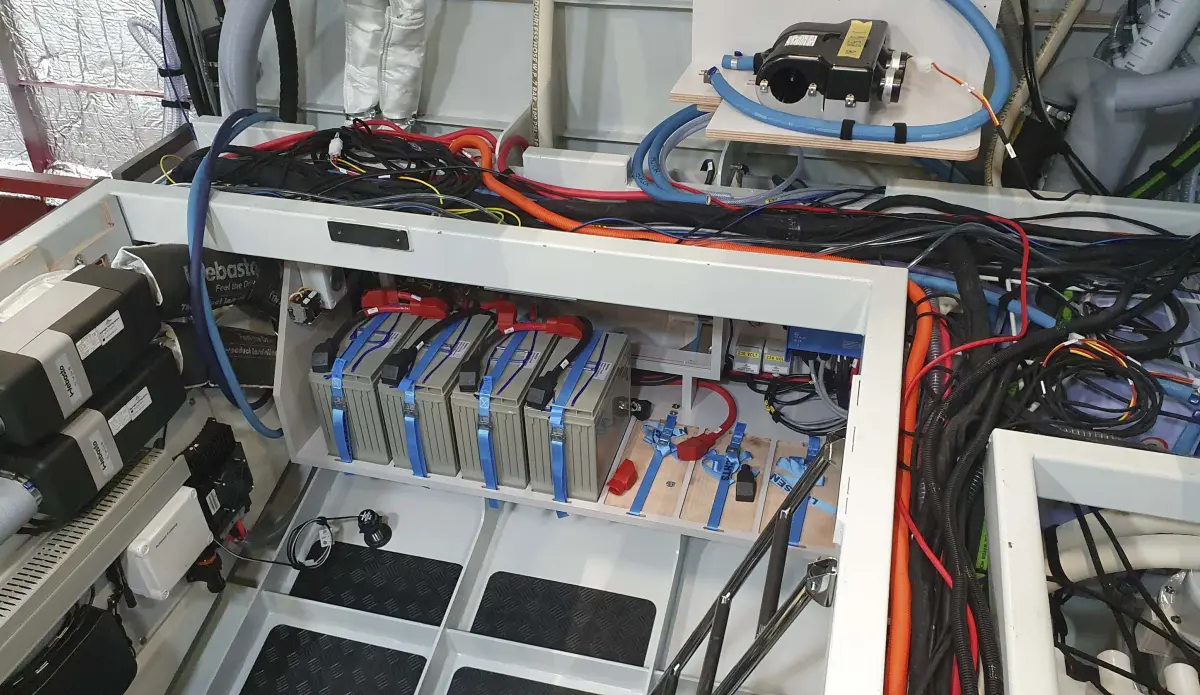

Technical installation

I am put back on the transport system and they now drive me down the road, across the car park and along the harbour to a large hall. There they carefully shove me inside. The gate closes and I cannot get out now until I am completely finished. Then the technicians began installing my “nervous system” and “organs”: piping, wiring, insulation, tanks, and the first parts of my beating mechanical heart. It felt a bit like a giant puzzle of which I am the finished picture.

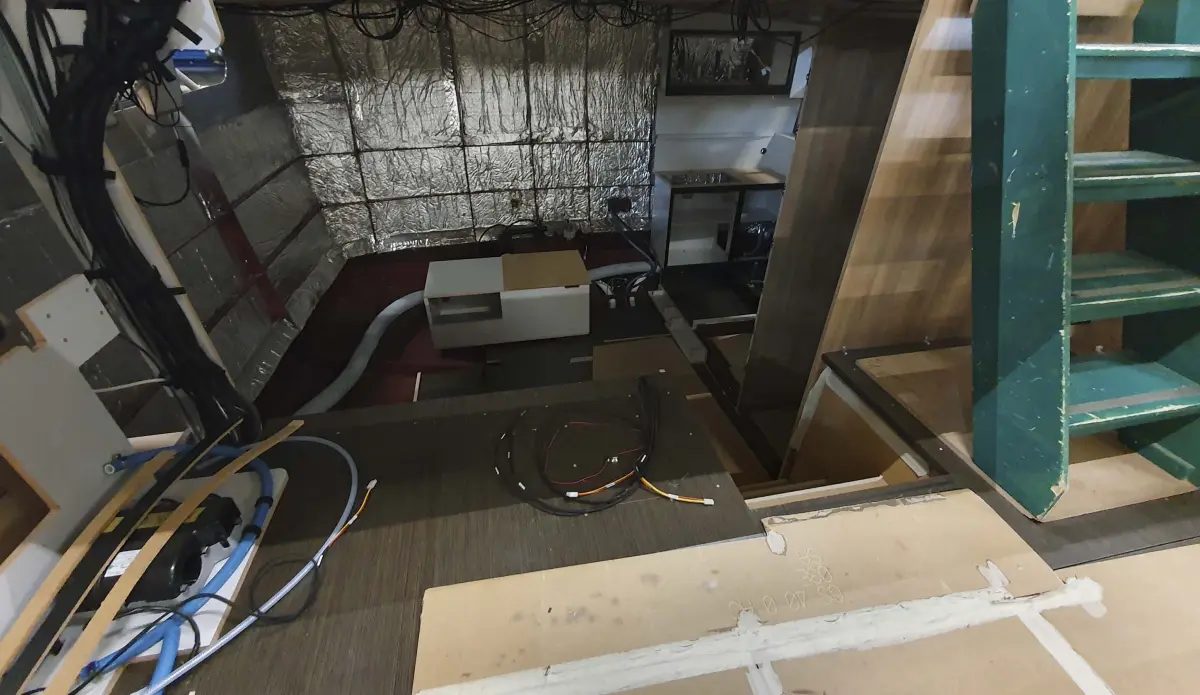

Interior construction (where I am as of the middle of June!)

And here I stand: right in the middle of the production line, while the interior team is working hard to make me just as beautiful inside as outside. Wall panels, floors, cabinetry – all carefully fitted. Each day, I gain more character. Soon I will be fully furnished to welcome you in complete comfort.