In the world of yacht construction, efficiency, accessibility, and quality are paramount. At Linssen Yachts, these principles...

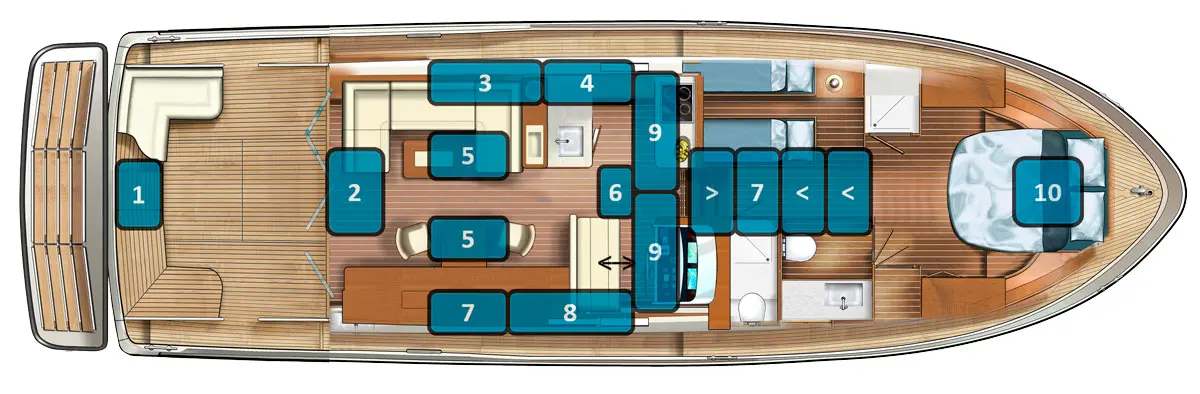

In the world of yacht construction, efficiency, accessibility, and quality are paramount. At Linssen Yachts, these principles are not just aspirations; they are deeply ingrained in our approach to engineering and design. Central to this approach is the "Ten Main Modules" principle for our engine room layout and positioning of all technical modules.

Imagine a meticulously organized blueprint where every component, from batteries to water tanks, diesel tanks to waste tanks, bow thrusters to stern thrusters, generators to climate control systems, is strategically placed in precisely the same location across all yachts. This is the essence of our "Ten Main Modules" principle.

By adhering to this principle, we achieve several key advantages:

In the world of yacht construction, efficiency, accessibility, and quality are paramount. At Linssen Yachts, these principles...